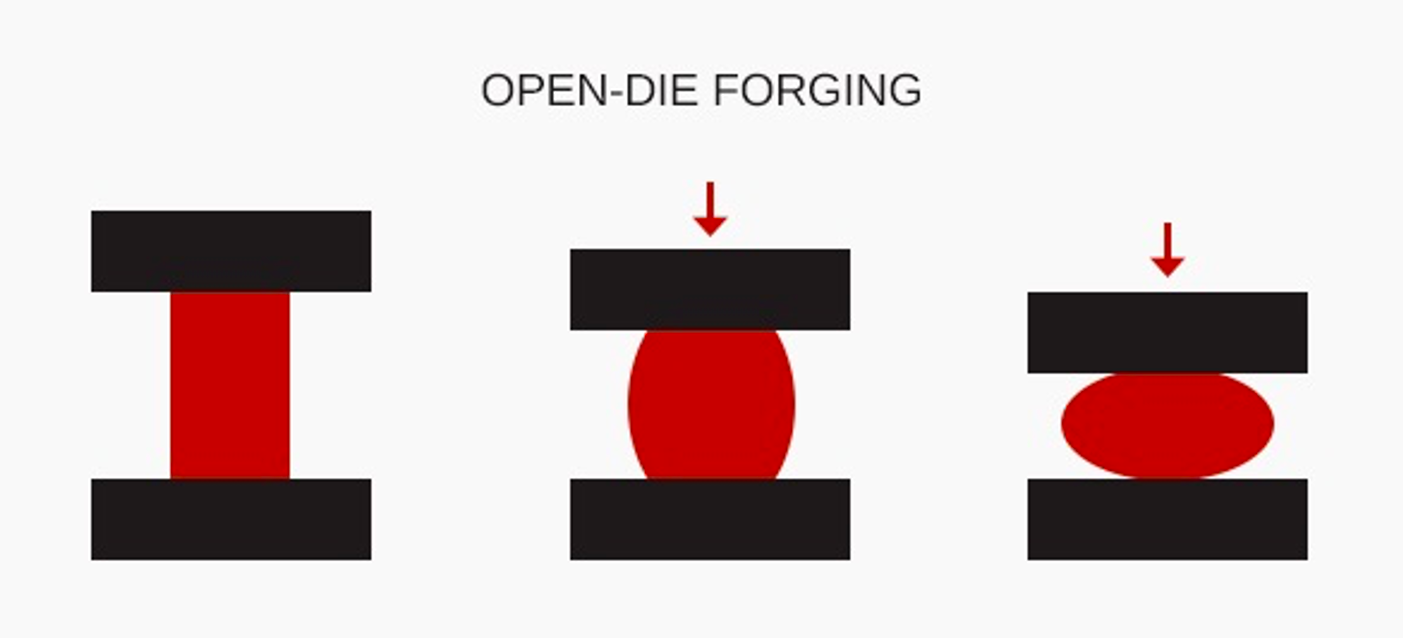

OPEN DIE FORGING

Open die forging, a versatile and custom metal shaping process, stands in contrast to closed die forging. Industries such as aerospace, defense, and heavy machinery favor open die forging for crafting intricate and large components to specific design standards. Much like the precision involved in open die forging, ISO flange and uni flange adhere to rigorous standards in the realm of piping systems. ISO flanges ensure standardized, efficient connections in industrial piping, while uni flanges offer adaptability.

Open die forging is a forging process that involves shaping a piece of hot metal by applying pressure or blows between a series of flat or partially-shaped dies. Unlike closed die forging, which uses fully enclosed dies to shape the metal, open die forging offers more flexibility and customization in the shaping process. This method is especially well-suited for the production of large, intricate parts that may be challenging to create using other forging techniques. Industries like aerospace, defense, and heavy machinery often rely on open die forging to manufacture customized components. To achieve the desired shape while preserving the metal’s strength and integrity, the metal is heated to the appropriate temperature and then placed between the dies, where it is shaped by the application of force through hammering or pressing. The dies, typically made from high-strength tool steel, are meticulously machined to meet specific design requirements.